|

Beijing Torch SMT Equipment Co.,ltd

|

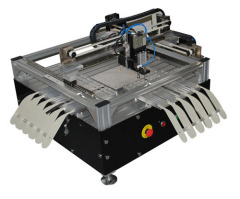

BGA3200 Hot Air Repair Station/ Automatic Repair Station system

| Payment Terms: | T/T,L/C |

| Place of Origin: | Beijing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

BGA3200 mainly include accurate Optical Position and Pick & place System, Hot Air Reflow Soldering System, Software Control System.

BGA3200 Hot Air Repair Station

BGA3200 Introduce:

1\ BGA3200 Hot Air Rework Station integrated structure design, can repair different sizes of BGA, QFP, CSP etc)

2\ BGA3200 mainly include accurate Optical Position and Pick & place System, Hot Air Reflow Soldering System, Software Control System.

Optical Position and Pick & place System:

A\High precision linear guiderail and turning platform can realize X-Y-Z direction and Nozzle adjust by Φ angle (360) and four dimensions

B\CCD, optical device and soft color splitting technology is composed of high precision optical mounting system, which can directly observe PCB pad and chip PIN foot overlap, position accurately and easy to operate, Max BGA size that can be mount is 50*50mm

C\High-fi CCD camera provides dual output signals of PAL and VGA, has amplifying, micro-adjust, focus automatically, software operation function, software operating functions, image BGA chip and PCB on LCD with 30X optical zoom.

D\BGA3200 mounting accuracy is ±0.02mm.

Hot Air Reflow Soldering System:

A. BGA3200 uses up and down individual heating system (temperature control, temp test), Large-size dark IR preheating at bottom, big power hot air heating at the top.

B. International advanced Dark-IR large size heating plate to avoid uneven heating to lead warpage. Dark IR (2-8 micron wavelength, the advantage of dark IR is that white and black have the same absorption and refractive rate, different parts of the component will not result in temperature difference due to different colors), dark IR is 2-8 micron un-visible light, the working life is about 1 million hours.

C. Heating head at the top used Germany heating chip, special structure design will give even rotating wind to reach better welding effect. Different sizes of hot air nozzle can change flexibly, can turn at any angle.

Software Control System:

1, High precision welding system: de-soldering and welding process is controlled by computer software automatically, limitless different of set temperature can be stored in the computer according to the specific requirements of welding technology curve and BGA rework curve.

2\Each technical curve can achieve the temperature curve simulations (40 segments temperature curve control) to improve the quality of welding. At the same time, two temperature probes, one for temperature measurement and control of the heating region, and the other can be stick on the welded components to test the actual temperature for the amendments to the temperature value of the heating region

3, Reflow soldering temperature profile generated automatically and stored in the computer, they can call at any time. LCD screen displays real-time temperature curve. Also shows two sets of temperature values and working time.

4, High-quality PC (Windows XP) system and BGA rework station system software, you can set reflow parameters according to the component characteristics.

BGA3200 Technical Parameter:

Size | 1100*720*620mm |

Total power | 2000W |

Hot Air heating at top | 800W |

Dark IR preheating | 1200W |

Working voltage | 220V(50Hz) |

Control mode | Manual/Automatic/program |

Mounting Accuracy | +/-0.02mm |

Position system | Double color soft light splitting technology |

PCB size | Max:400*300mm Min:30*10mm |

PCB thikness | 0.5-3mm |

Software control system | Based on WINDODS control software |

Mounting component size | Max:70*70mm Min:1*1mm |

Pick-up strength | 2.0N |

Temperature control system | Intelligent K type temperature control system, closed loop control |

PCB transmission | Software control, move automatically |

PCB driving system | High precision guiderail |

Technical curve | 40 segments temperature control |

Weight | About 50kg |

Spare part and accessories: BGA Re-balling station 1 (standard) De-soldering wick 1 (standard) Clear solution 1 box (standard) Flux solder 1 tin/ 100g (standard) Vacuum pan 1 (optional) BGA template Different BGA shall be customize | |

Related Search

Collision Repair System

Working Station System

Repair Tool

Repair Kit

Tire Repair

Tyre Repair

More>>