|

Beijing Torch SMT Equipment Co.,ltd

|

Reflow ovens

| Price: | 2375.0 USD |

| Payment Terms: | T/T, T/T, T/T, T/T |

| Special Groups: |

reflow soldering machine (6)

|

| Place of Origin: | Beijing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

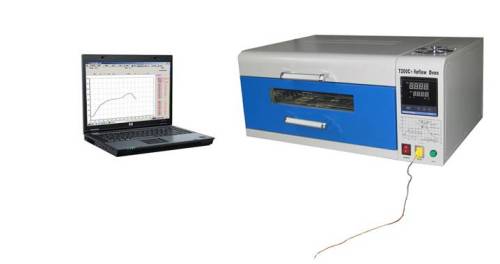

Cost-effective Desk Reflow Oven utilizes forced air convection heating technology and PC software interface to make an accurate temperature profile

Desk Reflow Oven Features:

Cost-effective Desk Reflow Oven utilizes forced air convection heating technology and PC software interface to make an accurate temperature profile quickly and easily. T200C+ is a fine temperature profile model with temp testing capable of lead-free soldering.

·PC interface software control and visional operation

·Heating mode: Infrared ray + Hot air convection

·Effective working table area: 360mm *230mm

·Real-time temperature testing function fills the blank of SMT industry overall world for adjusting the temperature at the real time.

·Patented heater installation® for heating evenly

·Patented forced air cycling and ventilating technology® for extremely uniform temperature profiling across the board.

·Patented oven door actuating device® for no vibration after PCB welding.

·It satisfies all welding requirements of 0201 resistance and capacitance, fine pitch QFP, SOP, PLCC, BGA, CSP and so on. It meets the requirements of small batch and multimode production. It is also suitable for laboratory and research institute..

T200C+ features

Computer control

Operate parameters by computer software can meet different welding requirement.

Computer control

Operate parameters by computer software can meet different welding requirement.

1.High precision ,multi- functions

It breaks through the shortages such as the difficulty of meter control program, the difficulty of modify parameter, limited storage of temperature curve. It adopts the software for temperature control, which is produced by Torch itself. The temperature curve can be set intuitively. And a large number of temperature curves can be stored. Analysis and statistics function, printing function.

Batch set 40 segments temperature curve

Real time testing with temperature curve

Test the temperature curve of soldering at every time. During the process of welding, the actual temperature can be displayed at the same time. It is convenient to adjust and control the lead-free curve. Especially control the heat preservation zone and the melting zone

Viewable operation, The real time display of temperature and the real time observation of the welding process. It is the best choice for science research and teaching.

Real time testing with temperature curve

Test the temperature curve of soldering at every time. During the process of welding, the actual temperature can be displayed at the same time. It is convenient to adjust and control the lead-free curve. Especially control the heat preservation zone and the melting zone

Viewable operation, The real time display of temperature and the real time observation of the welding process. It is the best choice for science research and teaching.

Testing temperature curve

temperature curve: real temperature curve and history temperature curve can be analyzed, it is convenient to improve.

Technical Parameter:

Temperature control segment | 40 segment, The segment can be set in computer according to the actual requirement. | |

Temperature-zone numbers | Single-zone and multi-segment | |

Temperature control system | PC control system ,SSR non-contact output | |

Temperature accuracy | ± 2 ºC | |

Warm-up time | 3min | |

Temperature range | Room-temperature -360ºC | |

Heating supply | Infrared ray + Hot air convection | |

Effective working table area |

| |

Welding time | 3min ± 1min | |

Temperature curve | It can be set ,adjusted and tested according to the actual requirement . | |

Cooling system | Transverse flow equal cooling | |

Rated voltage | AC single-phase, 220V; 50Hz | |

Rated power | 3.8KW | |

Mean power | 1.6kw | |

Weight | 35 kg | |

Dimension | L * W * H 610* 510 * 310mm |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!