|

Beijing Torch SMT Equipment Co.,ltd

|

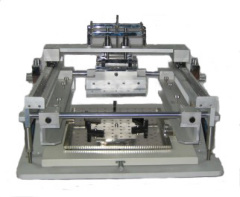

Stencil printer/ Semi-auto high precision stencil printer

| Price: | 2416.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Beijing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Double-sized PCBs printer, X, Y, Z, and angle position and adjustments for exact stencil-to-board alignment

Semi-auto Stencil Printer T1000

Semi-auto Stencil Printer T1000 provides fine X, Y, Z, and θ adjustments for exact stencil-to-board alignment resulting in precise, fine pitch printing for solder paste.

·Dual size of PCB printer, magnetism thimble support and fix PCB.

·Dual squeegee runs on the double parallel guiderail, they can ups and downs individually to realize the printing process of forward -> backward, backward->forward.

·Dual squeegee for clean and convenient application of solder paste

·Stencil lift just by press the button of air handspike

·High precision linear guide assures smooth manual squeegee stroke with its unique adjustable angle-of-attack for precise single or dual direction printing

·Fine X, Y, Z, and θ adjustments for exact stencil-to-board alignment

·Double switch button operation to complete the two-time printing process, east to operate.

Maximum print area | (300*400mm) |

Adjusts to various size frames: | Frame holder accepts any size stencil frame up to (400*500m) |

Adjustable dual squeegee pressure/speed: | Manual |

Linear squeegee guide: | Yes |

Squeegee material | stainless steel(other material can be ordered) |

Adjusting accuracy | <0.01mm |

Repeat accuracy | <0.03mm. |

Ideal printing speed | 500pcs/min |

Accessories: | Thimbles 8 Support shelves 6 Inner hexangular spanners 1 Nuts and bolts 6 |

Work principle: (more details see User Manual)

1\put PCB(Printed circuit board) at the bottom of stencil and fix well;

2\put solder paste on the inside of the stencil, scraper is moved by guide of driving device, solder paste is printed on the PCB through the hole of the stencil.

3\Take out of printed PCB boards and put it into turnover case

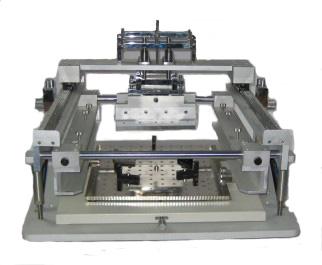

High precision linear guide | |

3 axes moving platform | |

Stencil holder can be adjusted, air handspike support to lift stencil |

.jpg)